Difference between revisions of "Photoelectron Spectrometer XPS and UPS"

Jump to navigation

Jump to search

Cmditradmin (talk | contribs) |

Cmditradmin (talk | contribs) |

||

| Line 9: | Line 9: | ||

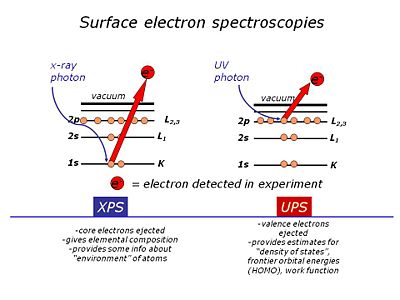

[[Image:Surface_electron_spectroscopies.jpg|thumb||400px |XPS uses high energy X-ray photons to excite “core” electrons in the near-surface region UPS uses lower energy photons in the deep UV region to excite valence electrons.]] | [[Image:Surface_electron_spectroscopies.jpg|thumb||400px |XPS uses high energy X-ray photons to excite “core” electrons in the near-surface region UPS uses lower energy photons in the deep UV region to excite valence electrons.]] | ||

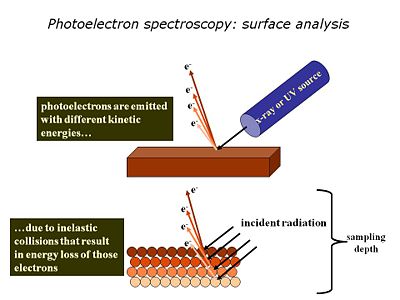

[[Image:PS-surfaceanalysis.jpg|thumb||400px |The small sampling depth of XPS and UPS arises because most of the photoelectrons generated do NOT make it out of the solid – they are scattered below the surface and not detected. Only those within 1-10 nm of the surface get out and can be analyzed.]] | |||

Revision as of 13:53, 21 April 2009

What is the Problem? OLEDs and OPVs consist of thin films of organic materials, sandwiched between contacting electrodes. We need analytical tools which tell us:

- Elemental composition of metal, metal oxide and organic surfaces (top 1-10 nm)

- The molecular state of those elements in that same region

- The frontier orbital energies which control rates of charge transfer, photopotentials, onset voltages, etc.

What is our approach? We use high-vacuum surface electron spectroscopies: X-ray photoelectron spectroscopy and UV-photoelectron spectroscopy to provide the elemental, molecular and energetic information we require about these materials.